New Products

Find Drill Bit Sharpening Machines, Drill Bit Sharpener, Drill Sharpener on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

Model No.: SEPDS/SEPDM/VA-POS/VA-POM/SS-DRC/FF-DRC

1. MITSUBISHI HSS milling shank drills SE High Precision Drill Series

1. MITSUBISHI HSS milling shank drills SE High Precision Drill Series  New HSS drill with newly developed proprietary D-STH surface treatment. Excellent for a wide range of work materials, wear resistant, lubricity and sharp cutting edge. |SEPDS/SEPDM

New HSS drill with newly developed proprietary D-STH surface treatment. Excellent for a wide range of work materials, wear resistant, lubricity and sharp cutting edge. |SEPDS/SEPDM  |What is D-STH treatment? Geometry of sharp cutting edge Proprietary D-STH surface treatment maintains sharp cutting edge even after drilling because D-STH treatment is a surface treatment that hardens the surface of tool substrate unlike a coating.

|What is D-STH treatment? Geometry of sharp cutting edge Proprietary D-STH surface treatment maintains sharp cutting edge even after drilling because D-STH treatment is a surface treatment that hardens the surface of tool substrate unlike a coating. Excellent welding resistance and smooth chip disposal due to better condition of tool surface Minute holes on a tool surface helps coolant penetrate into the holes, which result in the superior lubricity. The lubricity provides excellent welding resistance and chip disposal.

Excellent welding resistance and smooth chip disposal due to better condition of tool surface Minute holes on a tool surface helps coolant penetrate into the holes, which result in the superior lubricity. The lubricity provides excellent welding resistance and chip disposal. 2. MITSUBISHI New Generation Solid Carbide Drills WSTAR Drill Series

2. MITSUBISHI New Generation Solid Carbide Drills WSTAR Drill Series New generation solid carbide drills With new TRI-cooling Technology®

New generation solid carbide drills With new TRI-cooling Technology® Cutting Performance

Cutting Performance 3. KYOCERA Magic Drill DRX Type

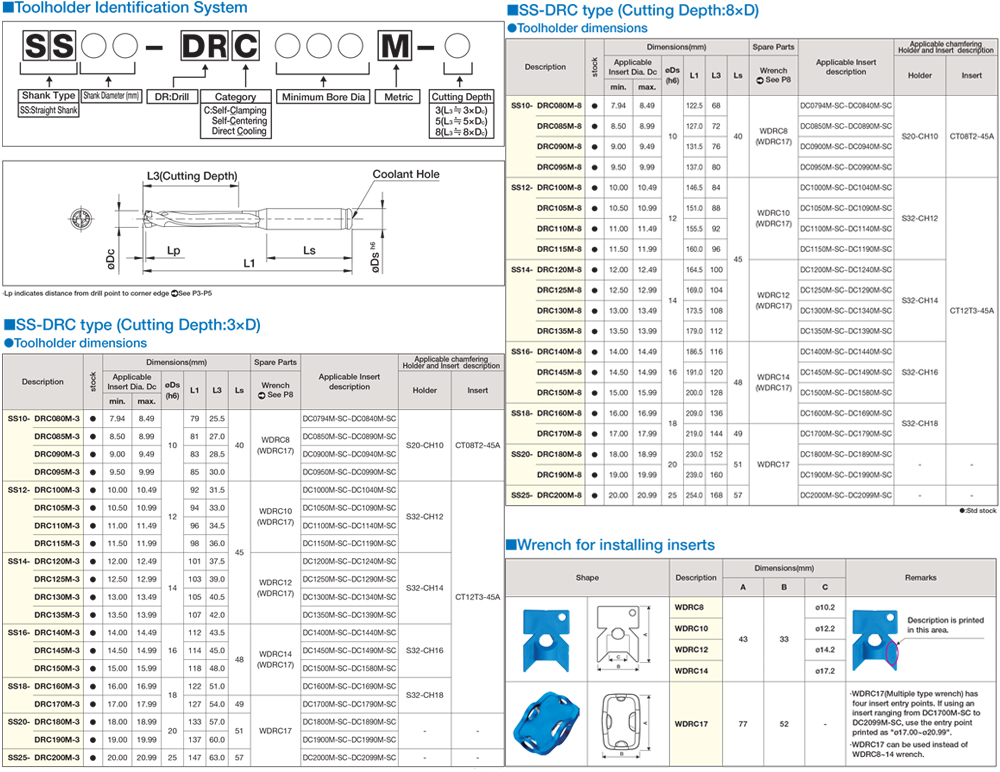

3. KYOCERA Magic Drill DRX Type 4. KYOCERA Magic Drill DRC Type

4. KYOCERA Magic Drill DRC Type

5. Please, let us know if you need more information about the following drills of our Mitsubishi Materials catalog

5. Please, let us know if you need more information about the following drills of our Mitsubishi Materials catalog

| Series | Details | Series | Details | Series | Details | Series | Details |

| 3KD | 3 shank types for portable power Tools (Triangular shank) | BRA | Low thrust due to absence of a chisel edge.Easy regrinding (NEW POINT DRILL) | BRB | Excellent cutting sharpness and chip discharge due to high rake type insert. {New point drill for bridge construction parts (l/d=3)} | BRL | Low thrust due to absence of a chisel edge. Easy regrinding (NEW POINT DRILL) |

| BRM | Excellent cutting sharpness and chip discharge due to high rake type insert. High efficiency, high accuracy machining. Suitable for stainless steel, mild steel and general steel drilling. (l/d=5) | BRMB | Excellent cutting sharpness and chip discharge due to high rake type insert. {Key point drill for bridge construction (l/d=5)} | BRS | Excellent cutting sharpness and chip discharge due to high rake type insert. High efficiency, high accuracy machining. Suitable for stainless steel, mild steel and general steel drilling. (l/d=3) | DCBSS | For machining materials such as sintered ceramics and quartz glass that cannot be machined with conventional drills. (Drill for hard brittle materials) |

| BRSB | Excellent cutting sharpness and chip discharge due to high rake type insert. {Key point drill for bridge construction (l/d=3)} | ||||||

| DCSSM | Due to the Diamond Coating original technology of our company, it excels in film adhesion. There is neither flaking off or cutting edge chipping. Consistent cutting is possible. (Medium, For non-ferrous material) | DCSSS | Due to the Diamond Coating original technology of our company, it excels in film adhesion. There is neither flaking off or cutting edge chipping. Consistent cutting is possible. (Short, For non-ferrous material) | EPSS | Special cutting edge geometry to prevent through hole burrs. (Plate pal) | GSD | Original manufacturing and coating technology for improved performance. (TiN, Straight shank) |

| GTD | Original manufacturing and coating technology for improved performance. (TiN) | GTTD | Special point geometry for minimal through hole burrs. (TiN, For steel frame) | GWSL | Suitable for extra deep hole drilling. (TiN, Extra long) | GWSS | Suitable for general and deep hole drilling. (TiN, For deep hole, Convolute flute) |

| GWTS | Suitable for general and deep hole drilling. (TiN, For deep hole, Convolute flute) | KSD | Sharp edge geometry for stainless steels up to 200HB. (Cobalt HSS, For stainless steel) | KTD | Suitable for difficult-to-cut materials. (Cobalt HSS) | LSD | Widely used for deep hole drilling. (Extra long) |

| LTD | Widely used for deep hole drilling. (Extra long) | MCS | For high accuracy and efficient drilling of CFRP. Unique diamond coating produces excellent wear resistance and a smooth hole surface. (For CFRP) | MGS | MGS drills are suitable for use with shrink fit holders. (SOLID GUN DRILL) | MHS | High backling strength and unique double margin. (WSTAR) |

| MMS | New grade DP7020 and a unique margin, developed specifically for stainless steel, complement high flow coolant holes. For high accuracy and efficient drilling of stainless steels. (WSTAR) | MNS | Four coolant holes is ideal for MQL applications. (WSTAR) | MQS | Long tool life and high efficiency drilling for steel and cast iron. (WSTAR) | MSP | SPOT DRILL |

| MVX | Ideal combination of outer CVD insert and inner PVD insert. High rigidity body that enabled L/D=6 deep hole machining. | MWE | Suitable for low to high speed cutting. For high accuracy and efficient drilling of steels, carbon steels and difficult-to-cut materials. (WSTAR) | MZE_MZS_STEP | Helical through coolant hole enables high speed machining (MZS type). (STEP DRILLS) | SD | For general drilling. (Straight shank) |

| SD1_100 | The diameter tolerance is - 0.007-0mm. (Straight shank, 1/100mm) | ||||||

| SDLS | It is recommended to use when long overall length is demanded for preventing collision with workpiece with high rigidity. For both machining center and manually operated machines. (STRAIGHT LONG SHANK DRILL) | SEPDM | Proprietary D-STH surface treatment provides sharp cutting edge, excellent welding resistance and smooth chip discharge. (SE High Precision Drill Series) | STAW | Wavy cutting edge design for good chip control. Highly rigid clamping system offers stability and reliability for small hole drilling. (Small Diameter Indexable Drill) | TAFS_TAFM_TAFL | High rigidity holder. Economical due to the use of 4 cutting edges. Various grades and chip breakers. |

| TAW | Wavy cutting edge design for good chip control. Serration geometry for accurate insert location. (Indexable Drill) | TD | For general drilling. (Taper shank) | TTD | Special point geometry for minimal through hole burrs. (For steel frame) | VAPDM | Highly efficient drilling and long tool life have been achieved with the newly developed Violet coating. (Standard drill depth : less than 5 times the drill diameter) (Medium, High precision) |

| VAPDMSUS | Our new design and the violet coating enable high efficiency drilling and long tool life for processing stainless steels. (Medium, High precision, For stainless steel) | VAPDS | Highly efficient drilling and long tool life have been achieved with the newly developed Violet coating. (Standard drill depth : less than 3 times the drill diameter)(Short, High precision) | VAPDSCB | Unique geometry offers high efficiency counter boring. Excellent chip breaking and flat counterbored surface.(Short flute length, High precision, For counter boring) | VAPDSSUS | Our new design and the violet coating enable high efficiency drilling and long tool life for processing stainless steels. (Short, High precision, For stainless steel) |

| VCHSM | A suitable geometry for high hardness (60 HRC) material drilling. | VCSSS_3MM | First recommendation for pilot hole drilling of hardened material. {Short, For steel (3mm shank series)} | VSD | Straight shank | VTDS | Short, Taper shank |

| MAE_MAS | Pre-hole drilling for rolled tap. Helical through coolant hole enables high speed machining (MAS type). Specialized in aluminium and cast iron drilling. High hole accuracy. | MINI-MVS | Straight cutting edge that combines the chips evacuation and cutting edge strength improvement. Double margin achieves the optimum balance and precision in small diameter drill. MVS-X02- =Drill for guide hole Dimensions = 0+0.014, Hole depth=2DC (WSTAR) | MSE | Wide flute for preventing chip jamming. Stable, small diameter machining. | MVE | New grade DP1020 offers long tool life for a wide range of work materials. The unique wavy cutting edge provides excellent sharpness and rigidity and helps to control wear at the periphery. (WSTAR) |

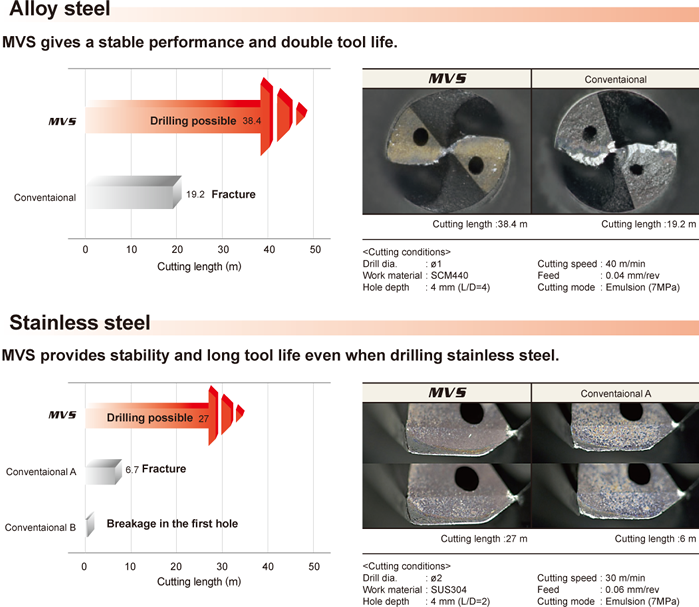

| MVS | New grade DP1020 offers long tool life for a wide range of work materials. Unique coolant supply technology, TRI-cooling offers high machining efficiency. (on drills over ø6) (WSTAR) | MWS | For high accuracy and efficient drilling of steels, carbon steels and difficult-to-cut materials. | MZE_MZS | Excellent chip disposal. Helical through coolant hole enables high speed machining (MZS type). |

|

Contact us if you need more details on Concrete Drill Bit. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Concrete Drill Bit、Concrete Drill Bit. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Concrete Drill Bit. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Concrete Drill Bit、Concrete Drill Bit. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Tools > Cutting Tools